In the realm of heavy - duty industrial operations, the efficient and safe handling of heavy steel coils is a critical task. Roll clamps have emerged as indispensable tools for this purpose, offering a reliable solution for lifting and transporting heavy steel coils. This article delves deep into the technical principles of roll clamps and the application techniques for multi - coil diameter adjustment, aiming to provide users with professional guidance and practical advice.

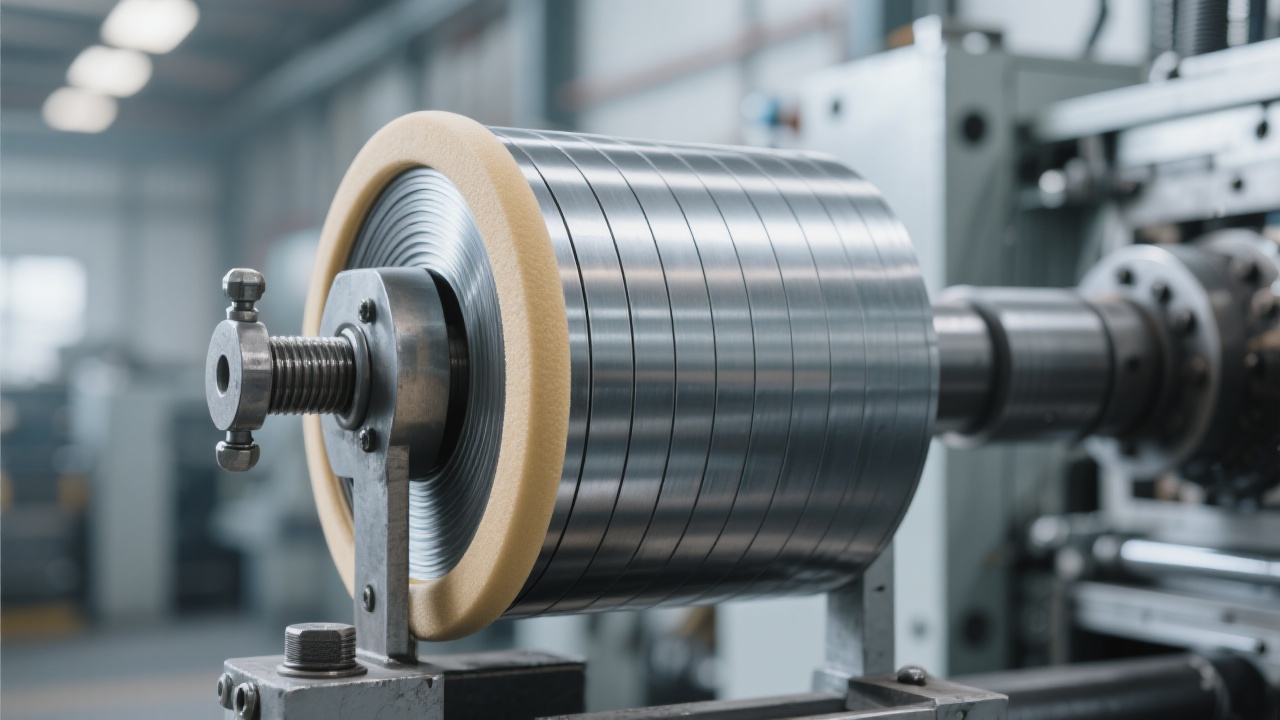

Roll clamps operate on a gravity - based mechanism. This ingenious design allows the clamp to automatically adjust its gripping force according to the weight of the steel coil. When the clamp is lowered onto the coil, the force of gravity causes the jaws to close around the coil, providing a secure grip. The support device design of roll clamps is also a key factor in their functionality. It is engineered to distribute the weight of the coil evenly, reducing stress on the coil and preventing damage.

One of the most remarkable features of roll clamps is their ability to adjust to different coil diameters. This flexibility is crucial in various industrial settings where coils of different sizes are commonly handled. The adjustment process is relatively straightforward, yet it requires precision. By following the correct procedures, operators can quickly and accurately set the clamp to fit the specific coil diameter. This not only improves the efficiency of the lifting process but also enhances safety by ensuring a proper grip.

Roll clamps are highly versatile and can be used in a wide range of industrial applications. In steel mills, they are used for loading and unloading steel coils from storage racks or transportation vehicles. In non - ferrous metal processing plants, roll clamps are employed to handle coils made of aluminum, copper, and other non - ferrous metals. Heavy machinery manufacturing and metallurgical plants also benefit from the use of roll clamps, as they provide a safe and efficient way to lift and move heavy coils. Even in general industrial environments, roll clamps can be used for various lifting tasks, offering a cost - effective solution.

Compared with other similar products in the market, our roll clamps stand out for their ease of use and safety features. Some competing products may require complex set - up procedures or additional tools for adjustment, while our roll clamps are designed to be user - friendly. The gravity - based operation eliminates the need for external power sources, reducing the risk of mechanical failures. In terms of safety, the even weight distribution design and the ability to securely grip coils of different diameters significantly reduce the chances of accidents.

Let's take a look at some real - world customer cases to see the actual effects of our roll clamps. A large steel mill in [Location] was facing challenges in handling steel coils of different sizes efficiently. After implementing our roll clamps, they were able to increase their lifting efficiency by 30%. Another non - ferrous metal processing plant reported a 20% reduction in coil damage incidents after switching to our roll clamps.

We'd like to engage with our readers. Do you have any experience with using roll clamps? Or do you have any questions about their operation? Please leave your comments below and share your thoughts. You can also participate in the following vote: Do you think the multi - coil diameter adjustment feature is the most important aspect of roll clamps? [Yes/No]

In conclusion, roll clamps are a powerful and versatile tool for heavy steel coil lifting. Their unique technical features, combined with their adaptability to different industrial scenarios, make them an ideal choice for businesses looking to improve efficiency and safety. If you are interested in learning more about our roll clamps or want to explore how they can benefit your operations, click here to get in touch with us.