Handling aluminum ingots safely and efficiently remains a significant challenge across global metal processing plants. Industry data reveals that on average, aluminum ingot handling accounts for up to 25% of workplace incidents related to heavy material transport, while bottlenecks caused by inefficient gripping tools reduce production throughput by nearly 30% in some facilities.

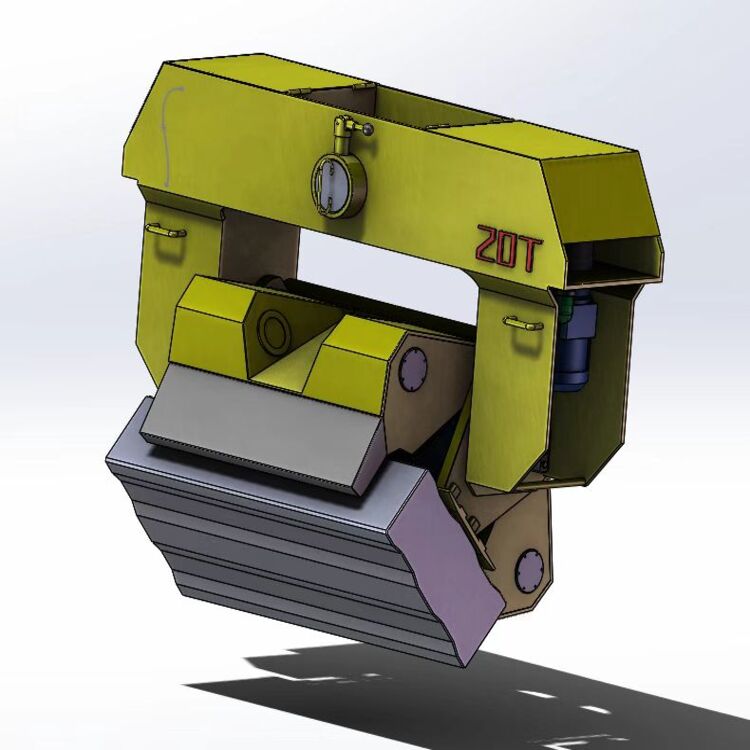

The introduction of a tailor-made high-strength aluminum ingot clamp addresses these critical issues by delivering enhanced safety features alongside remarkable improvements in handling efficiency. Below, we explore how its innovative design and robust construction redefine the standards for aluminum ingot handling tools.

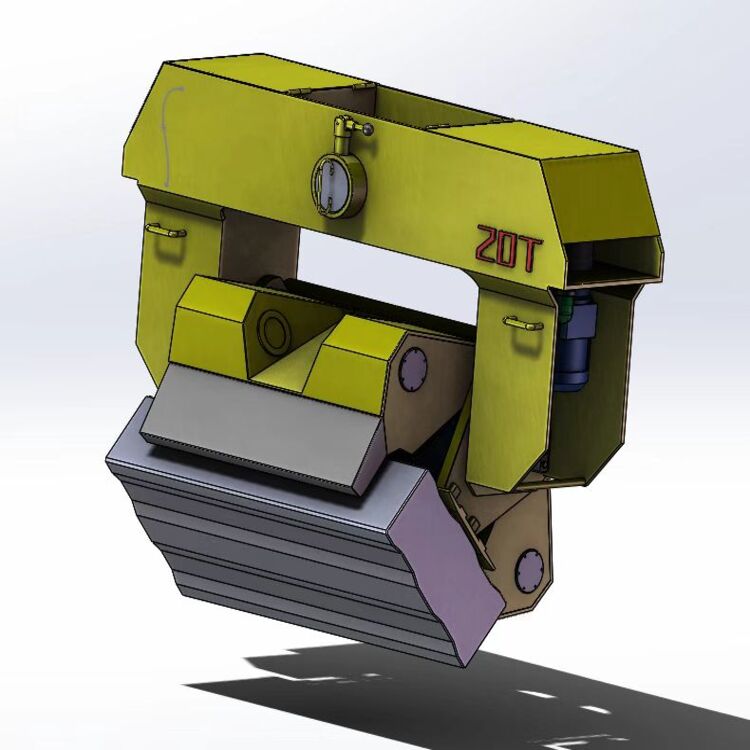

Ease of operation is paramount in high-paced industrial environments. The aluminum ingot clamp integrates an intuitive interface that minimizes operator fatigue and reduces training time by approximately 40%, based on case studies from multiple manufacturing plants. Ergonomically engineered handles and quick-release mechanisms enable swift attachment and detachment, cutting average handling time per ingot by nearly 50%.

This user-centric design not only enhances day-to-day productivity but also drastically lowers human errors associated with complex handling tools, thereby improving overall safety records.

Central to this clamp’s outstanding performance is its engineered clamping system, which exerts a consistent grip force exceeding 10,000 Newtons. This ensures ingots weighing over 150 kilograms remain securely held during transport, virtually eliminating accidental drops.

Industrial clients report a 35% reduction in load slippage incidents after switching to this clamp from conventional gripping tools. The mechanism’s stability has been rigorously tested under varied operational stresses, meeting and exceeding international safety standards such as ISO 12100 for machinery safety.

Constructed from aerospace-grade steel alloy with corrosion-resistant coatings, this clamp offers exceptional longevity even in harsh aluminum production environments with constant exposure to metallic dust, lubricants, and temperature fluctuations from -10°C to 70°C.

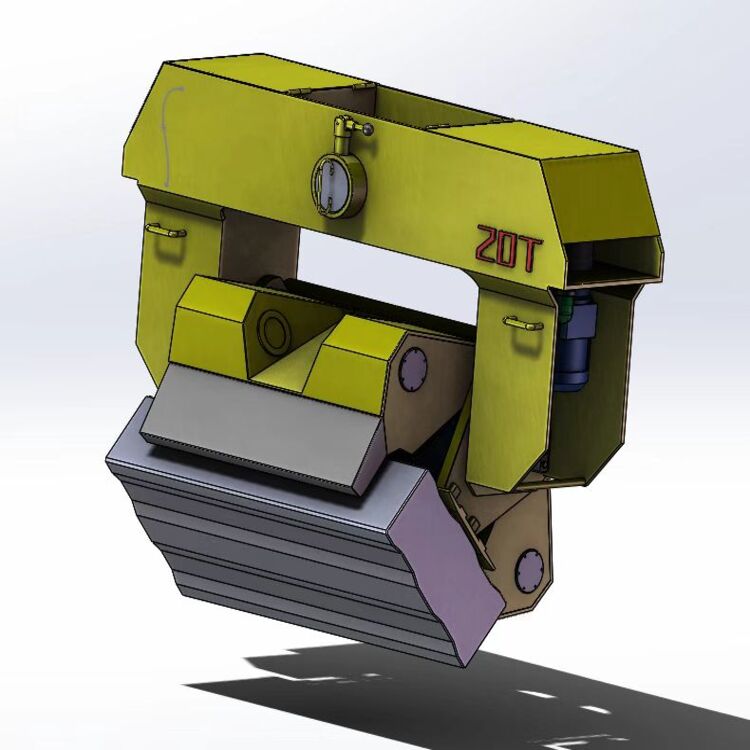

Field data from a large-scale smelting plant indicate the clamp’s operational life exceeds 10,000 handling cycles before comprehensive maintenance is required, translating into reduced downtime and lower total cost of ownership (TCO) for operators.

Maintenance efficiency is a critical consideration in heavy equipment. This clamp’s modular design facilitates swift replacement of wear components without disassembling the entire unit, reducing maintenance turnaround by 60% compared to legacy models.

The inclusion of built-in visual wear indicators and accessible lubrication points further empower on-site technicians to conduct preventive maintenance proactively, avoiding costly unplanned outages.

Global aluminum manufacturers have widely adopted this clamp, citing measurable improvements in both safety and productivity:

| Key Metric | Before Clamp | After Clamp | Improvement |

|---|---|---|---|

| Ingot Handling Time (per unit) | 120 seconds | 60 seconds | 50% Reduction |

| Clamp-Related Safety Incidents (Monthly) | 4 | 1 | 75% Reduction |

| Maintenance Downtime (Hours/Month) | 8 | 3 | 62.5% Reduction |

“Switching to this clamp has transformed our handling line. The operators feel safer and faster, and our throughput has never been higher.” — Plant Manager, European Aluminium Smelter

Companies aiming to boost operational excellence and worker safety in aluminum handling can rely on this high-strength ingot clamp as a cornerstone tool. Its blend of user-friendly operation, powerful grip, long-lasting materials, and optimized maintenance ensures continuous improvements in plant performance.

Adopting such advanced handling equipment helps unlock not only productivity gains but fosters a culture of safety and reliability, essential for staying competitive in the metals industry today.

Discover How This Clamp Transforms Your Aluminum Handling Efficiency