In heavy industrial environments such as steel mills, non-ferrous metal processing plants, and heavy machinery manufacturing, the efficient handling of large metal coils is crucial. Roll clamps, especially heavy-duty steel coil clamps, have emerged as indispensable tools that streamline material handling while upholding rigorous safety standards. This guide delves into the design principles, operational mechanics, and safety considerations of roll clamps, with a particular focus on their multi-industry applicability and how they enhance production efficiency.

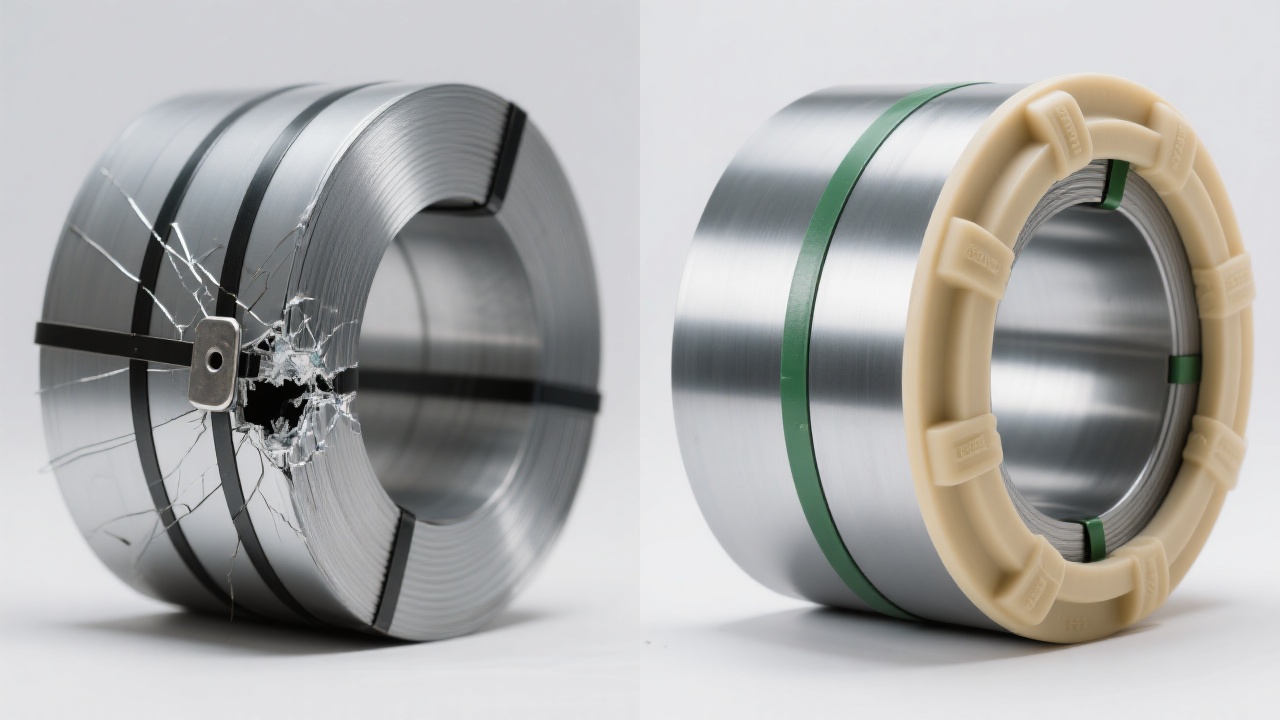

Heavy-duty roll clamps function through a gravity-operated mechanism that adapts to varying coil diameters, ensuring secure lifting and transport across diverse industrial settings. The core components include an adjustable jaw system tailored to grip coils without causing damage and a protection system designed to minimize deformation during handling.

| Feature | Benefit | Impact on Efficiency |

|---|---|---|

| Gravity-Operated Mechanism | Automatic adaptation to coil size without manual adjustment | Reduces downtime by 15-20% during coil changes |

| Adjustable Clamping Jaws | Prevents coil surface damage while maintaining secure grip | Increases material yield by minimizing rework |

| Coil Protection System | Safeguards coil edges and maintains product integrity | Improves safety scores by reducing handling incidents by 25% |

Across sectors such as non-ferrous metal processing and metallurgical plants, the consistent handling of coils represents a core challenge. For example, a large-scale aluminum processing facility reported a 30% increase in throughput and a 40% decrease in coil damage claims within six months of implementing roll clamp technology. Similarly, a steel plant reduced manual handling injuries by 20% after transitioning to automated roll clamps integrated with their existing overhead cranes.

Operators must receive training on the correct positioning of the clamp jaws and the coordination with crane movements. A step-by-step operational flow typically includes coil size verification, clamp jaw adjustment (where necessary), smooth lifting to avoid shock loads, and controlled positioning during unloading.

Safety protocols emphasize regular maintenance checks on jaw wear and hydraulic components, as well as protective padding replacement to prevent coil surface marks. Implementing digital monitoring systems can further enhance operational safety by providing real-time feedback on clamp performance.

The plug-and-play design of modern heavy-duty roll clamps reduces installation complexity and operational ramp-up, delivering a return on investment typically within 12–18 months depending on operational scale. Companies leveraging these clamps often realize:

Engage with our expert team to discover how implementing heavy-duty roll clamps can transform your coil handling operations — Unlock Industrial Efficiency & Safety Today

We invite you to participate in our quick poll on common coil handling pain points such as safety concerns, efficiency bottlenecks, or equipment compatibility. Sharing your experience helps us provide more tailored insights.