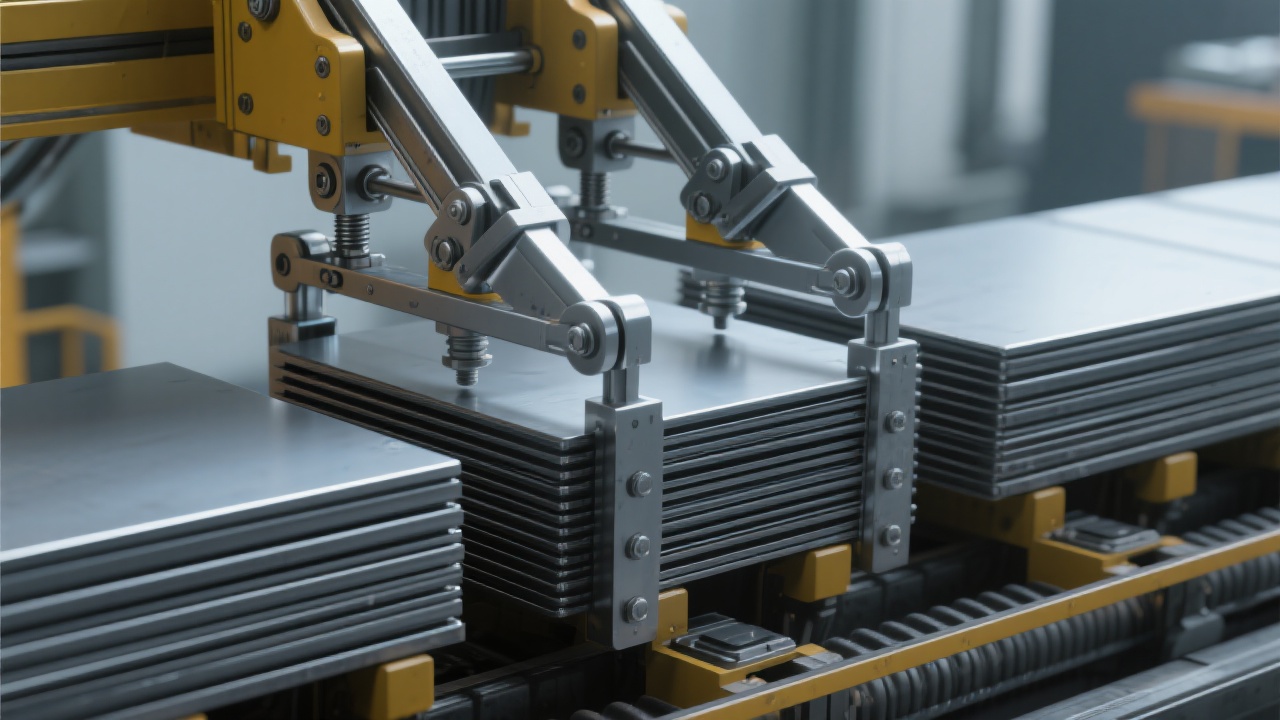

In heavy industries like steel manufacturing, optimizing the handling and transportation of massive steel ingots is critical to operational efficiency and safety. Enter the hydraulic steel ingot clamp — a powerful, adaptable technology designed to meet the demanding conditions of steel production lines, heavy casting transport, port logistics, nuclear power plant installations, and metal processing sectors. With load capacities spanning from 8 to a staggering 550 tons, these clamps transform steel ingot handling into a smooth, secure, and time-saving operation.

Traditional steel ingot handling often relies on manual or semi-automated processes, which bottleneck throughput and elevate risk exposure. Hydraulic steel ingot clamps mitigate these issues through an automatic gripping mechanism powered by robust hydraulic systems. This automation notably increases cycle speed, reducing loading and unloading times by approximately 35-50% based on field reports from leading steel producers.

The clamps’ precision grip ensures minimal ingot slippage, enabling conveyor systems and overhead cranes to operate at optimal flow without interruption. Such efficiency gains cascade down the production chain, contributing directly to higher output and lower labor costs.

Welding shops and foundries handling castings upwards of 100 tons face tremendous challenges during transport between stations. Hydraulic clamps provide consistent and evenly distributed gripping force, minimizing the risk of material deformation and accidental drops.

According to a case study from a leading European foundry, adapting hydraulic ingot clamps reduced transport-related damage incidents by 60% over a 12-month period, while simultaneously enhancing operator confidence and reducing insurance claims.

Ports that handle steel products and raw ingots require robust equipment to expedite loading/unloading without compromising safety. The hydraulic clamps’ load range from 8 to 550 tons makes them perfectly suited for container terminals and bulk cargo docks.

Their ability to automatically adjust grip force based on ingot size enhances versatility, reducing changeover times drastically. This results in throughput increases of up to 40% in optimized port operations documented in recent industry audits.

Nuclear sector projects impose stringent safety and quality standards, requiring equipment that delivers flawless performance under critical conditions. Hydraulic steel ingot clamps used in nuclear plant construction undergo rigorous testing to ensure reliable operations without compromise.

Their redundant safety locking mechanisms and corrosion-resistant materials ensure security during transportation and assembly of critical steel components. Feedback from a recent nuclear power project highlights zero incidents related to ingot handling since clamp deployment commenced.

By integrating hydraulic clamps, casting and metal processing facilities have achieved measurable reductions in workplace injuries associated with manual handling of heavy ingots. Automatic hydraulic pressure adjustment allows operators to handle various ingot shapes safely.

Maintenance cycles are prolonged due to the clamps’ modular design and low wear hydraulic components — further decreasing operational downtime by up to 25%, based on operational data from multiple manufacturing sites.

| Application | Efficiency Improvement | Safety Enhancement | Maintenance Benefit |

|---|---|---|---|

| Steel Production Line | +35% to 50% faster loading/unloading | High grip precision reduces accidents | Minimal hydraulic component wear |

| Heavy Casting Transport | Reduced transport delays by 40% | Significant drop in damage incidents | Modular clamps simplify upkeep |

| Port Logistics | +40% throughput increase | Automatic load adaptation for safety | Durable under harsh environments |

| Nuclear Facilities | Consistent, error-free handling | Redundant safety and corrosion resistance | Compliant with strict regulatory standards |

| Metal Processing | Downtime reduced by 25% | Automated pressure control for safety | Extended service intervals |

Experience the future of steel ingot handling — Discover how hydraulic steel ingot clamps optimize your production line today

Join the conversation:

Which challenge in your steel handling process would you like to improve with hydraulic clamp technology? Leave your questions or experiences below, and our experts will provide tailored insights to help you elevate your operations.