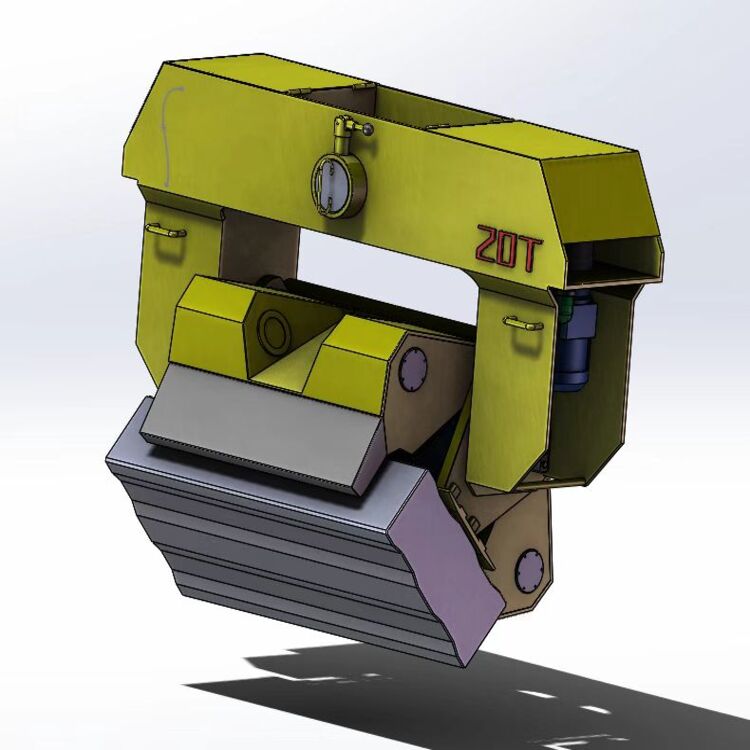

In the high-stakes environment of aluminum ingot transportation, precision and safety aren’t just desired — they’re mandatory. Operators face challenges like ensuring a secure grip during stacking, heat treatment, and shipping cycles. Enter the new-generation, user-friendly aluminum ingot clamp: a game-changing tool engineered not only to elevate safety standards but also to slash operational downtime and training complexity.

Moving from novice to skilled operator often demands significant training for traditional gripping tools, which involve complicated locking systems prone to mishandling. The latest clamp design, however, eliminates this barrier with intuitive mechanisms—no complex instructions or lengthy supervision needed.

By prioritizing ergonomic controls and automatic adjustment features, these clamps accommodate diverse ingot sizes seamlessly. One user remarked, “I was surprised how quickly I felt confident using the clamp—with zero trial errors within my first day.” Such seamless onboarding dramatically reduces downtime and error rates.

Safety incidents during ingot transport often stem from slippage or uneven clamp pressure. This clamp uses high-strength material with advanced gripping teeth geometry—delivering consistent clamping force that adjusts dynamically under load. Factory testing reveals a zero-slip success rate in over 1,000 operational cycles, a remarkable improvement compared to conventional clamps with 5–7% slippage rates.

| Clamp Type | Average Clamping Force (kN) | Slip Rate (%) |

|---|---|---|

| Traditional Aluminum Clamp | 18 | 6.5 |

| User-Friendly High-Strength Clamp | 25 | 0.0 |

Whether in the heat of a furnace environment or the bustling dockyards, clamps must excel under all conditions. This latest clamp features heat-resistant coatings and corrosion protection, ensuring longevity and minimal maintenance in harsh climates.

Logistics teams report a remarkable 30%+ boost in handling productivity post-adoption. “Our transport times tightened drastically without compromising safety — it feels like each ingot is locked in place, letting us work confidently,” notes a logistics supervisor.

While this clamp simplifies operation, some key best practices ensure maximum benefit:

Implementing these safeguards allows the clamp to deliver on its promise: “Say goodbye to slippage risks, and embrace a new era of efficient, confident handling.”

Unlock Reliable Efficiency – Let Every Aluminum Ingot Land Steadily and Safely Discover Our Advanced Clamps Now