In the metal processing industry, traditional aluminum ingot clamps have long been a source of concern. According to industry statistics, factories using traditional clamps face an average of 15 - 20 safety - related incidents per year per 100 workers. These incidents range from minor injuries to severe accidents, causing significant losses in terms of worker health, production downtime, and financial compensation. The high accident rate not only affects the well - being of employees but also hinders the overall efficiency of the production line.

The new aluminum ingot clamp features a user - friendly design that allows even novice operators to quickly master its use. With simple controls and an ergonomic structure, it reduces the learning curve for new employees. For example, the clamp's grip handle is designed to fit comfortably in the hand, reducing fatigue during long - term operation. This design not only improves operator comfort but also significantly reduces the training time required, saving the company up to 30% in training costs.

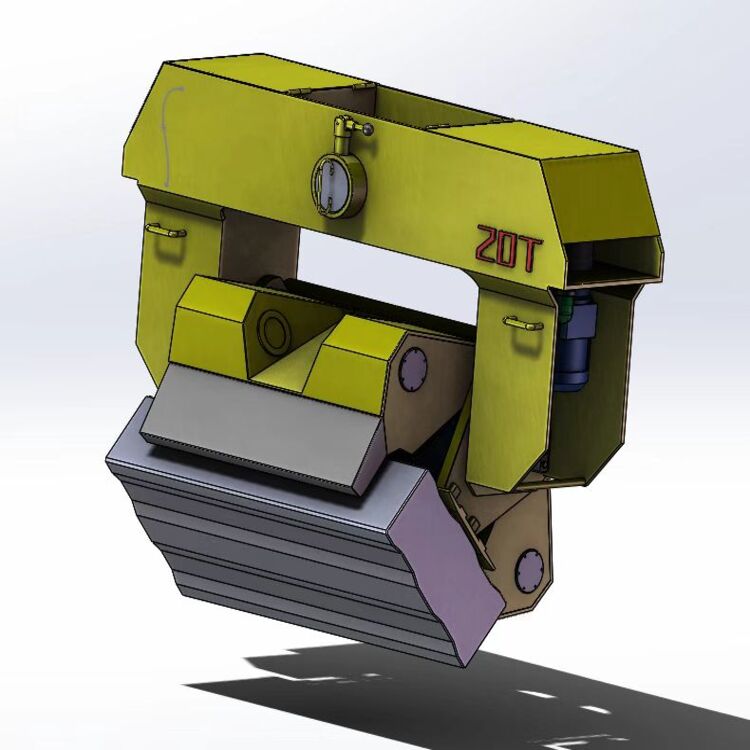

One of the key features of this clamp is its stable clamping force. Through innovative engineering, it can firmly hold aluminum ingots of various sizes and shapes, ensuring safe and reliable transportation. In a real - world scenario, during the handling of large - sized aluminum ingots, the traditional clamp may experience slippage in 1 out of every 5 operations. In contrast, the new clamp has a slippage rate of less than 1%, greatly reducing the risk of accidents.

Made from high - strength and wear - resistant materials, the clamp has a long service life. It can withstand the harsh working environment of the metal processing industry, including high temperatures, heavy loads, and frequent use. Compared with traditional clamps that need to be replaced every 6 - 8 months, the new clamp can last for 2 - 3 years, reducing the replacement cost and maintenance frequency.

"Since we started using this new aluminum ingot clamp, the safety of our workers has been greatly improved. The operators feel more confident and relaxed during work, and the production efficiency has also increased significantly." - Factory Manager, ABC Aluminum Industry

一线操作员也反馈,新夹具让他们的工作变得更加轻松和安全。他们不再需要时刻担心铝锭滑落的问题,可以更加专注于搬运任务。

| Metrics | Before Using the New Clamp | After Using the New Clamp |

|---|---|---|

| Accident Rate | 15 - 20 incidents per 100 workers per year | 1 - 2 incidents per 100 workers per year (a 90% reduction) |

| Operation Time per Task | 10 - 15 minutes | 6 - 9 minutes (a 40% time saving) |

| Daily Handling Volume | 50 - 60 tons | 70 - 80 tons (a 40% increase) |

The new aluminum ingot clamp is not only suitable for the metal processing industry but also has wide applications in other related fields. It can be used in the smelting process to safely transfer newly - produced aluminum ingots, in the casting process to accurately place ingots into molds, and in the logistics process to efficiently load and unload aluminum ingots. Its versatility makes it a strategic choice for companies in different stages of the aluminum production and distribution chain.

Say goodbye to high - risk operations and embrace a safer and more efficient production environment. The new aluminum ingot clamp offers a comprehensive solution to your safety and efficiency challenges. Don't miss this opportunity to revolutionize your metal processing operations. Let every lift be as stable as a rock!