In the fiercely competitive steel manufacturing sector, the safe and efficient handling of high-temperature steel plates remains a critical operational challenge. Traditional clamping tools often fall short in adapting to the rigorous demands of modern steel plants, notably in heat-intensive environments such as hot rolling mills or continuous casting workshops. The integration of advanced hydraulic-driven plate clamps offers a transformative solution that combines automation, precision, and safety to elevate production workflows.

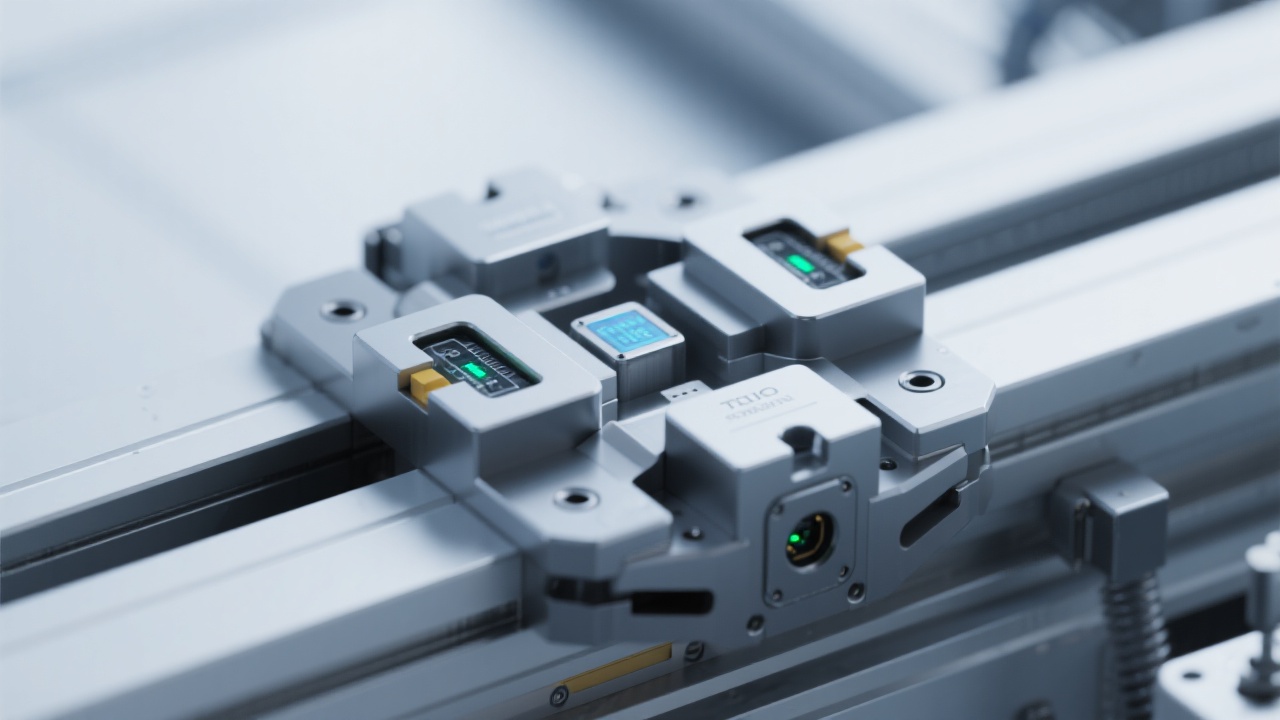

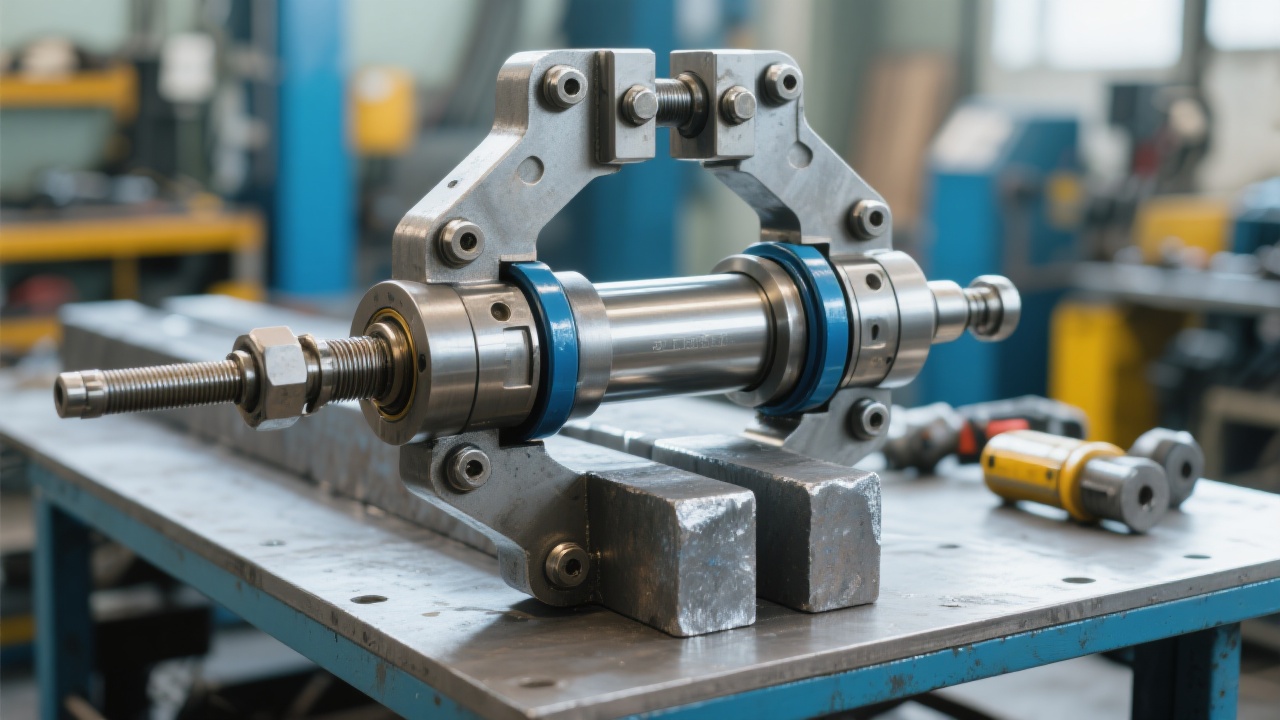

Hydraulic-driven plate clamps leverage precision hydraulics to enhance gripping force control and movement accuracy. Unlike manual or mechanically fixed clamps, hydraulic systems allow adjustable clamping pressure, enabling operators to safely secure steel plates without damaging their surfaces or compromising their structural integrity. This dynamic clamping force reduces the risk of slippage during lifts, especially critical when handling steel heated over 600°C.

The automatic open/close feature controlled by hydraulic actuators ensures rapid and consistent operation, significantly reducing cycle times. In typical hot-rolled steel production lines, this can translate into a 15-25% improvement in material transfer speed, as observed in case studies from leading integrated steelworks. Furthermore, these clamps integrate seamlessly with existing overhead crane systems, supporting synchronized motion and minimizing human intervention.

The versatility of hydraulic plate clamps proves beneficial across a range of steel production environments:

Real-world deployments underscore hydraulic clamps’ value: a leading steel producer reported a 20% reduction in handling-related downtime within six months of integration. Simultaneously, the automated clamping mechanism led to a 50% decrease in operator-related accidents, significantly lowering the associated costs and insurance premiums.

The table below summarizes comparative figures between traditional mechanical clamps and hydraulic-driven clamps over a standard production cycle:

| Performance Metric | Mechanical Clamp | Hydraulic-Driven Clamp | % Improvement |

|---|---|---|---|

| Material Transfer Speed (slabs/hour) | 40 | 50 | +25% |

| Operator Injury Rate (incidents/year) | 6 | 3 | -50% |

| Clamp Maintenance Frequency (times/year) | 8 | 4 | -50% |

Traditional clamps frequently expose workers to hazards from manual handling errors, inconsistent clamping force, and equipment wear. Hydraulic plate clamps eliminate many of these risks through:

“The shift to hydraulic-driven clamping technology marks a pivotal advancement in handling processes for high-temperature steel plates. Beyond boosting operational throughput, it decisively enhances workplace safety and aligns with ongoing digital factory automation trends.”

— Dr. Alan Hughes, Senior Consultant, Steel Manufacturing Technologies

These insights, combined with empirical data, underscore the mounting industry momentum toward hydraulic clamp adoption as a best practice for modern steel plants.

Considering the substantial gains in efficiency, safety, and durability, hydraulic-driven plate clamps represent a strategic investment for steel manufacturers aiming to secure competitive edge while reducing operational risks.