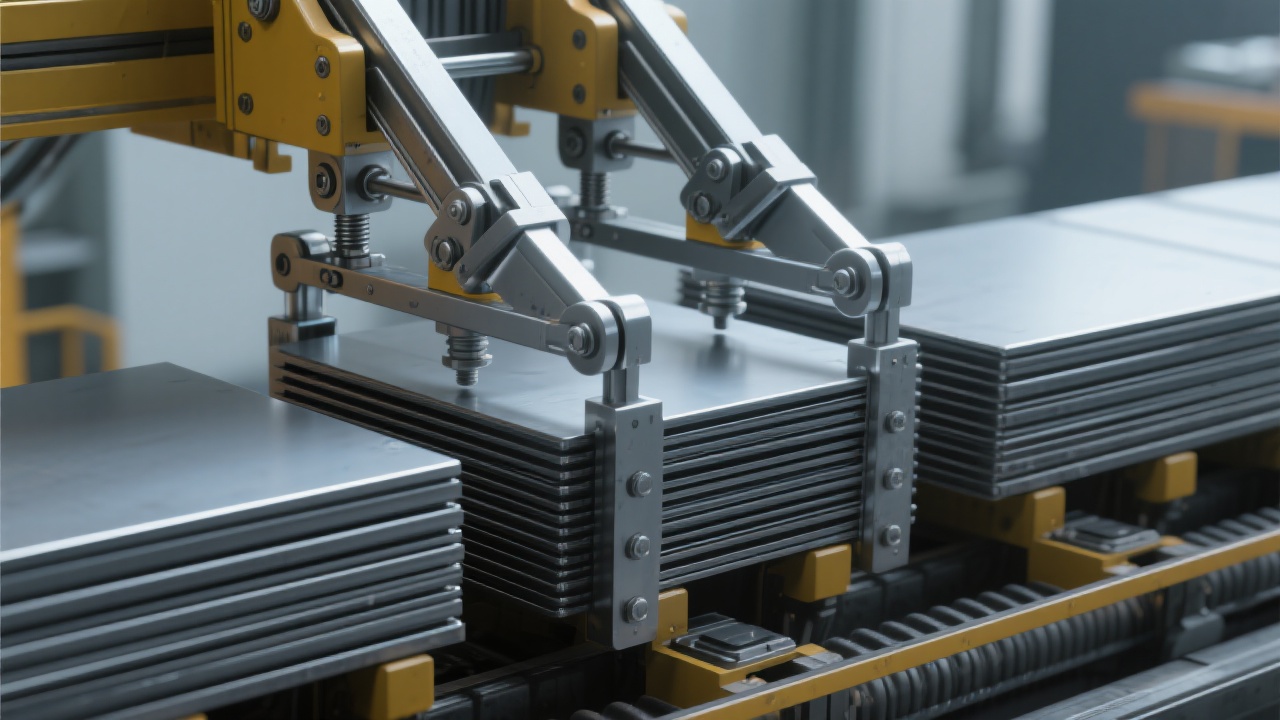

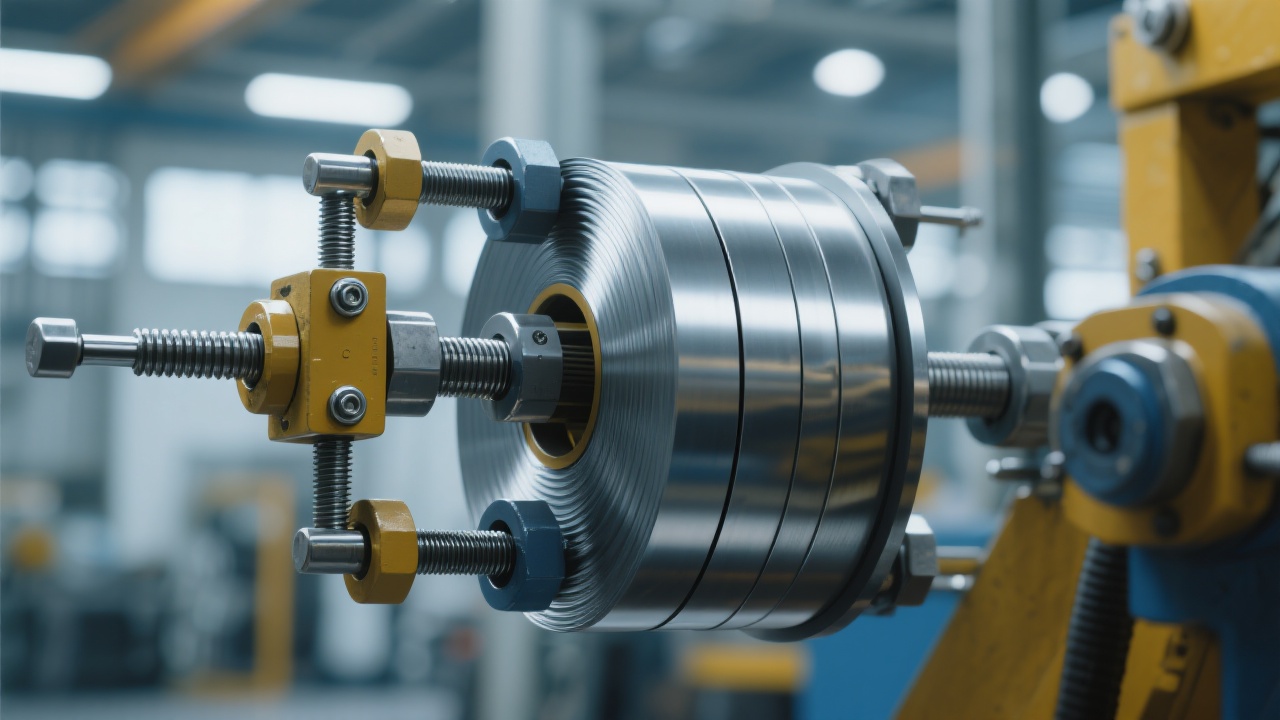

In the demanding environments of steel mills, non-ferrous metal processing, and metallurgy plants, the efficiency and safety of coil handling tools directly impact production outcomes. Rollers clamps—specialized heavy-duty steel coil lifting devices—are engineered to optimize these operations by seamlessly combining ease of use, adaptability, and coil protection. This article explores the technical advantages of roller clamps, their application across diverse industrial scenarios, and proven benefits backed by real-world success stories.

Roller clamps have become indispensable in various heavy industries:

The innovation behind roller clamps lies in three fundamental features uniquely engineered to improve workflow:

| Core Feature | Benefit & Impact |

|---|---|

| Gravity Operation Mechanism | Utilizes the coil’s own weight to increase grip force automatically, simplifying clamp engagement and reducing operator fatigue by up to 25%. This mechanical advantage enables quicker lifting cycles and safer handling under heavy loads. |

| Adjustable Coil Diameter Adaptability | Supports multiple coil sizes through precise adjustable jaws, eliminating the need for multiple clamp models. This flexibility cuts inventory costs by approximately 15% and enhances operational responsiveness. |

| Protective Polyurethane and Copper Padding | Integrates soft yet durable materials that minimize coil surface damage during lifting, preserving product quality and reducing rework by 20%. This protective layer is essential in non-ferrous and high-value coil handling. |

A comparative evaluation reveals significant efficiencies:

| Criteria | Traditional Clamps | Rollers Clamps |

|---|---|---|

| Safety Incidents (Annual) | 18 per facility | 4 per facility (reduced by 78%) |

| Operation Cycle Time | 4 minutes per cycle | 2.7 minutes per cycle (33% faster) |

| Maintenance Cost (Annual) | $12,000 | $7,200 (40% savings) |

Consider a leading steel manufacturing plant in Germany that implemented roller clamps across two production lines. After one year, the plant reported:

Such measurable enhancements underscore how roller clamps foster safer, faster, and more cost-efficient coil handling processes.

The roller clamp relies on a gravity-operated force amplification design. When the clamp is lifted by the crane, the coil's weight inherently increases the clamping pressure, ensuring a stable grip without additional hydraulic or pneumatic systems. Precision-engineered pivot points and adjustable jaws accommodate varying coil diameters, while integrated protective pads absorb and distribute pressure evenly to prevent material abrasion and deformation.

Standardizing roller clamps across operations establishes consistent safety protocols and reduces human error, critical in the strict workflows of steel processing plants. Their intuitive gravity mechanism minimizes operator training time, while adjustable settings support diverse coil sizes by a single device. This harmonization leads to a safer work environment, more predictable process timing, and scalable production improvements.

In your industrial setting, which roller clamp attribute do you prioritize the most?

Share your choice at our feedback platform and join industry peers in shaping future innovations!