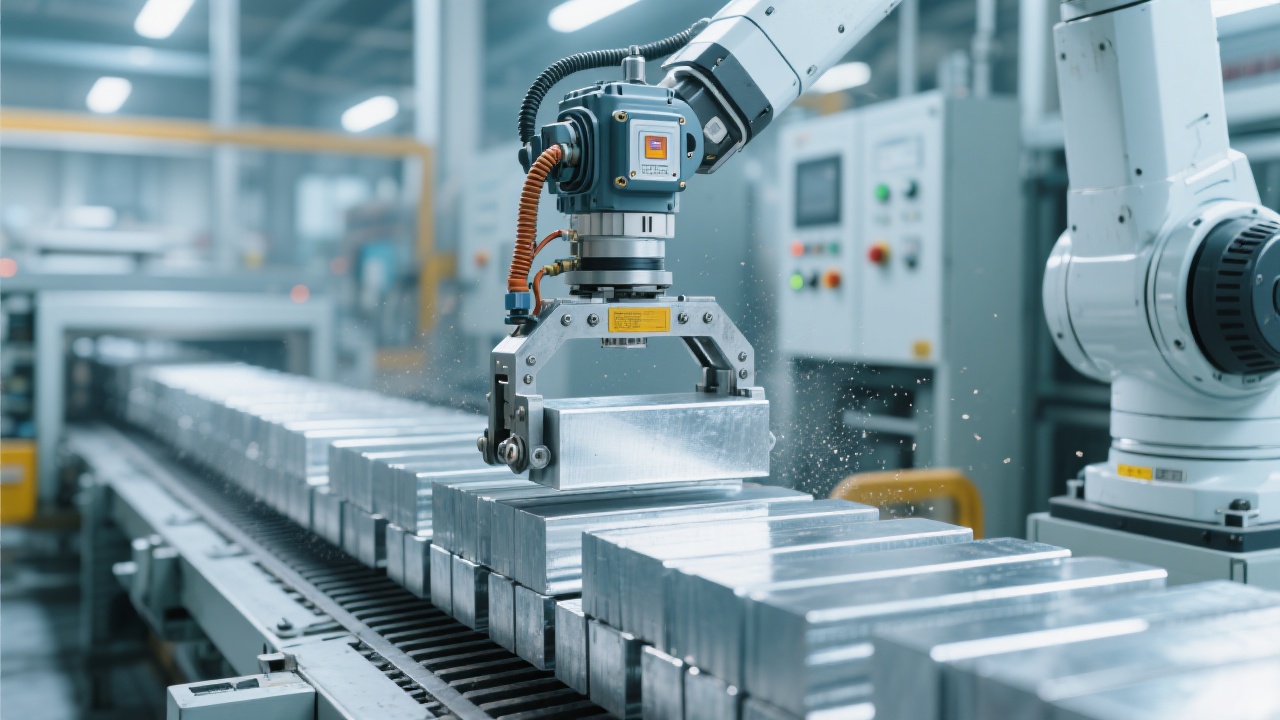

In the fast-paced aluminum industry, safe handling and transport of aluminum ingots are paramount. You may have wondered how to mitigate risks like slippage, deformation, or accidents during critical stages such as heat treatment and logistics. High-strength aluminum ingot clamps have emerged as indispensable tools that guarantee reliable holding and protection in harsh conditions. This article unveils their safety functions, structural advantages, and real-world impact on operational efficiency.

Historically, manual handling or generic gripping tools were employed to move aluminum ingots through the production chain. Such traditional approaches often led to avoidable hazards:

In contrast, purpose-designed aluminum ingot clamps provide a quantum leap in safety and process stability by securing loads firmly even at elevated temperatures and on complex transport routes.

The advanced clamps distinguish themselves with two core design features that directly address industrial pain points:

| Design Aspect | Benefit |

|---|---|

| High-Strength Heat-Resistant Materials | Structural integrity maintained under temperatures exceeding 600°C, enabling stable gripping during heating. |

| Innovative Clamping Mechanism | Uniform pressure distribution prevents ingot deformation, while ensuring a slip-resistant grip during high-frequency operations. |

These engineering breakthroughs mean the clamps not only endure the thermal stress of heat treatment but also maintain safety and efficiency across complex logistics chains.

Consider the case of a leading aluminum smelter in North America that integrated these clamps into their heat treatment workflow. Within six months, they reported:

“Since adopting these clamps, our heat treatment line is safer and faster. It’s a game changer for both safety and cost control.” — Operations Manager, North American Aluminum Smelter

These clamps aren't just tools; they act as catalysts for thorough process standardization. By ensuring consistent gripping force and uniform handling practices, they help enterprises:

For businesses facing persistent challenges like ingot surface damage, operational delays, or safety breaches during transport, these clamps offer a tangible solution. From source to shipping dock, they make every transfer rock-solid and risk-free.

If you have ever faced hidden costs stemming from ingot damage or slowing throughput in your aluminum production line, it’s time to reconsider your handling solutions. The right clamp design adapts seamlessly to your operation’s unique demands — whether it’s enduring continuous heat exposure or securing ingots on the move.

Are your current methods truly eliminating risk, or just managing it? Remember, securing quality and safety from the start directly translates into greater efficiency and competitive advantage.

Transform Your Aluminum Ingot Handling — Make Every Transfer Rock Solid