In the steel production industry, the choice of steel plate clamps can significantly impact production efficiency, safety, and cost control. This article provides a comprehensive comparative analysis between traditional steel plate clamps and high-efficiency power-driven clamps, aiming to offer valuable insights for steel enterprise management and technical procurement personnel.

The core of high - efficiency power - driven steel plate clamps lies in their advanced hydraulic drive system. Unlike traditional clamps, which often rely on manual operation or simple mechanical structures, the hydraulic drive system provides a stable and powerful clamping force. For example, in a large - scale steel production plant, traditional clamps may require 3 - 5 workers to operate simultaneously to lift a large steel plate, while the high - efficiency power - driven clamps can be operated by only one worker, reducing labor costs by up to 60%.

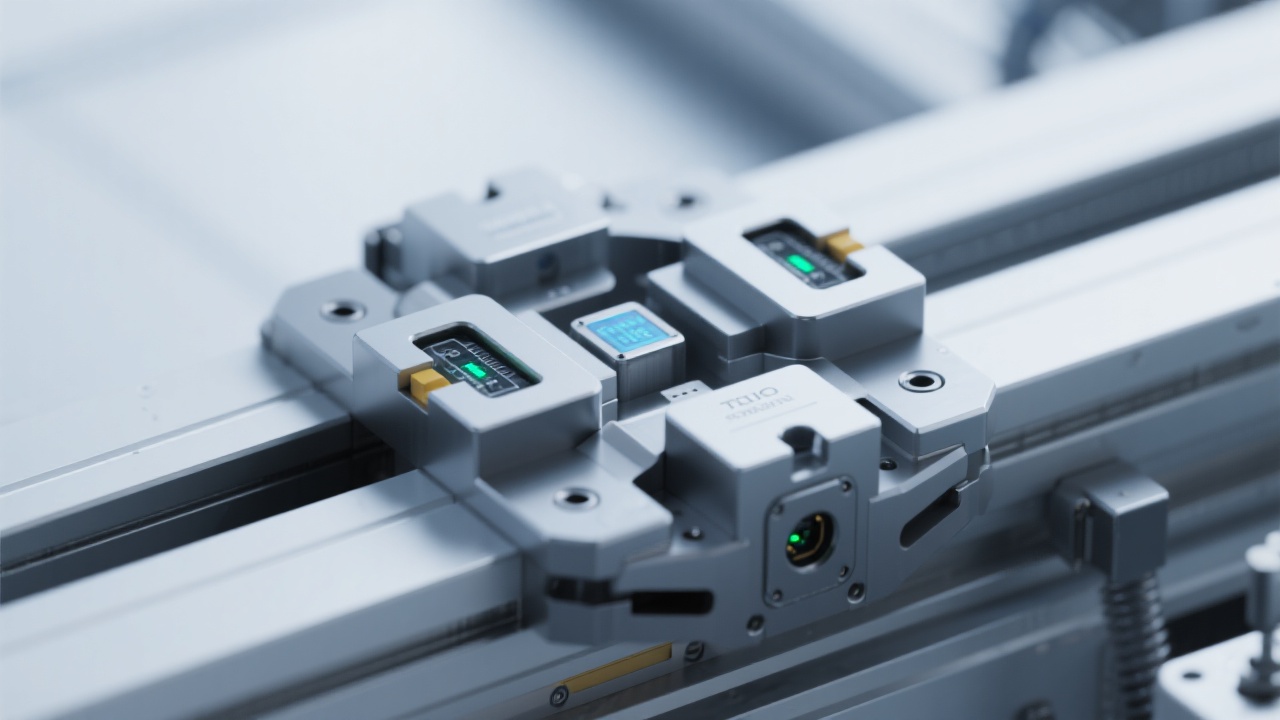

These clamps also feature precise clamping and automatic operation functions. The hydraulic system can adjust the clamping force according to the size and weight of the steel plate, ensuring a secure grip. In addition, the automatic switch function allows for quick and accurate movement of the steel plate, improving handling efficiency. In a continuous casting workshop, the use of high - efficiency power - driven clamps can increase the handling speed of steel plates by 40% compared with traditional clamps.

Safety is a top priority in steel production. Traditional clamps are prone to human errors during operation, such as improper clamping, which can lead to steel plate falling and cause serious safety accidents. According to industry statistics, in steel plants using traditional clamps, the probability of safety accidents related to steel plate handling is about 3% - 5% per year. In contrast, the high - efficiency power - driven clamps significantly reduce such risks. Their automatic operation and precise clamping functions ensure stable and safe handling of steel plates, reducing the probability of safety accidents to less than 1%.

In terms of efficiency, the difference between the two types of clamps is even more obvious. In a steel production facility, traditional clamps need to be manually adjusted and fixed for each steel plate handling, which is time - consuming. For example, it may take 5 - 10 minutes to complete the handling of a single steel plate. On the other hand, the high - efficiency power - driven clamps can complete the same task within 1 - 2 minutes, increasing the handling efficiency by 80% - 90%.

This efficiency improvement also has a positive impact on production continuity. In a hot - rolling mill, traditional clamps may cause production delays due to slow handling speed, resulting in an average of 2 - 3 hours of production downtime per month. The high - efficiency power - driven clamps can effectively avoid such delays, ensuring smooth production and increasing overall production capacity.

Cost control is crucial for steel enterprises. Traditional clamps not only require high labor costs but also have relatively high maintenance costs. The mechanical parts of traditional clamps are prone to wear and tear, and the replacement frequency of parts is relatively high. In contrast, the high - efficiency power - driven clamps have a more durable structure and a lower failure rate. Their maintenance costs can be reduced by about 50% compared with traditional clamps.

The high - efficiency power - driven steel plate clamps have a wide range of applications in different steel processing scenarios. In steel production facilities, they can be used for the initial handling of steel plates; in hot - rolling mills, they can quickly transfer steel plates between different processing equipment; in continuous casting workshops, they can accurately move the cast steel plates. In each scenario, they can significantly improve production efficiency and safety.

We encourage steel enterprise management and technical procurement personnel to share their experiences and opinions on the use of steel plate clamps. Do you have any questions or concerns about the high - efficiency power - driven steel plate clamps? Feel free to leave your comments below and let's discuss together!

Discover the benefits of high - efficiency power - driven steel plate clamps for your business!