%20Clamp-1.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

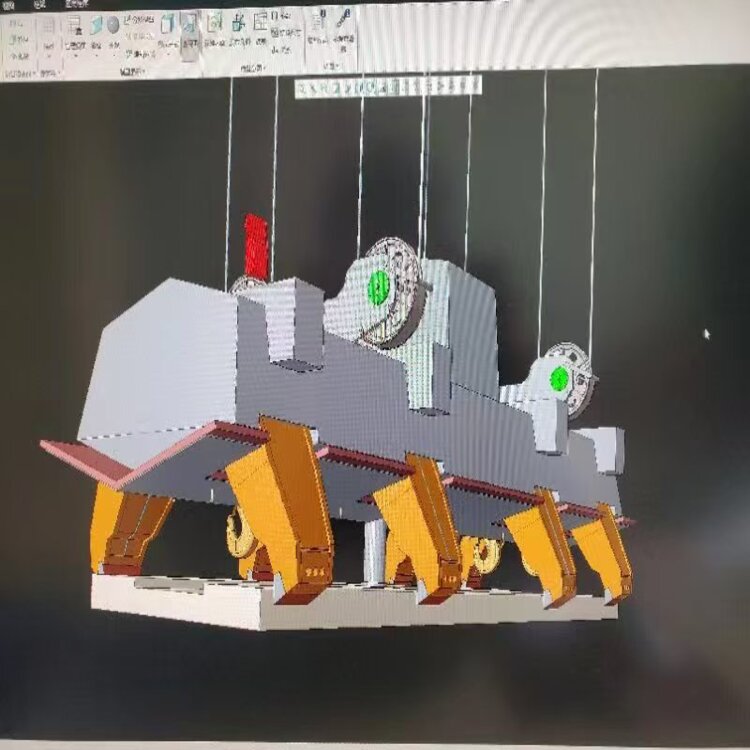

In the demanding arena of port logistics, steel plate handling remains one of the most challenging tasks. Operators grapple with inefficiencies and heightened safety risks caused by cumbersome equipment and unpredictable conditions. Enter high-strength alloy steel clamps — increasingly favored across the industry for their robust performance and reliability under harsh environments.

These advanced clamps stand out due to a synergistic combination of three critical features:

Each attribute directly translates to enhanced operational value in real-world port environments, where reliability and speed matter most.

%20Clamp-1.jpg)

A recent deployment of these clamps at a major North American port terminal demonstrated a remarkable 25% reduction in steel plate loading times. The automatic gripping mechanism eliminated operator fatigue-related errors, contributing to a 40% decrease in damage claims over six months.

Similarly, a steel production facility in Germany reported extending clamp service life by over 150% compared to traditional steel grips, while maintenance downtime dropped by 60%. These statistics, validated by on-site performance audits, underscore the asset's role in streamlining workflows and strengthening supply chain resilience.

| Performance Metric | Traditional Clamps | Alloy Steel Clamps | Improvement |

|---|---|---|---|

| Operational Efficiency | 100% | 125% | +25% |

| Maintenance Frequency | Quarterly | Biannual | +100% |

| Damage Claim Reduction | Base Rate | -40% | -40% |

The longevity of traditional clamps is frequently curtailed by corrosion and mechanical wear, leading to frequent replacements and safety hazards. High-strength alloy steel clamps mitigate these issues with:

More than just hardware, these clamps embody a long-term strategic investment that propels port logistics toward greater intelligence and sustainability. By enabling consistent, quicker, and safer steel plate handling, they free up human resources and reduce downtime, creating a virtuous cycle of productivity enhancement.

Industries adopting this technology report not only tangible cost savings but also improved compliance with increasingly stringent safety standards and environmental regulations. Such benefits contribute directly to sustaining competitive advantage in a rapidly evolving global logistics landscape.

Make Every Grab Safer and Faster – Upgrade to High-Strength Alloy Steel Clamps Today!